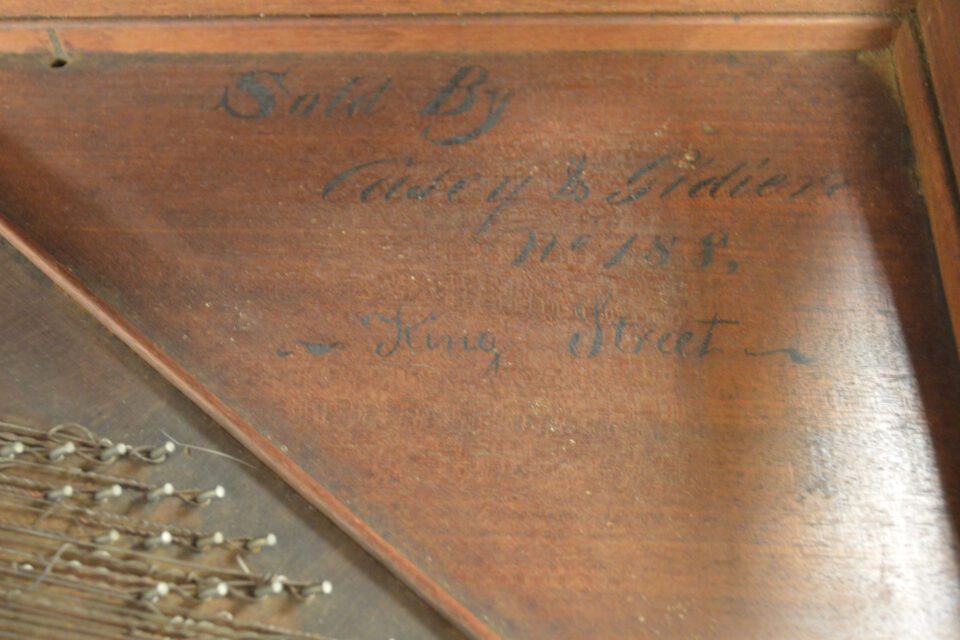

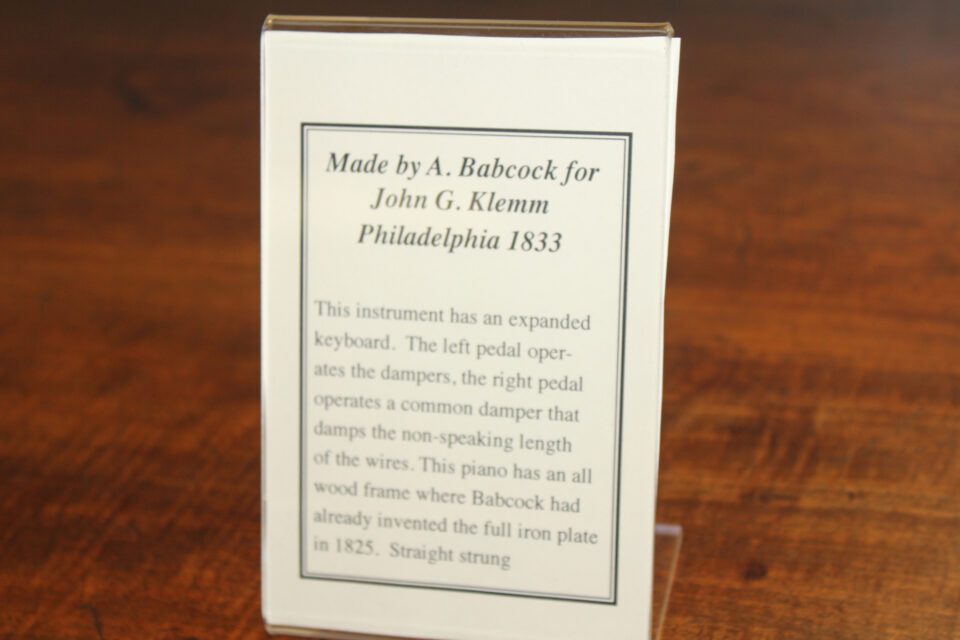

Alpheus Babcock was an extraordinarily innovative piano maker, best known for his invention of the one-piece cast iron string frame. Born in Massachusetts in 1785, he learned piano building from Benjamin Crehore. Alpheus and his brother, Lewis, established their own manufactory in 1809, and in 1811 Alpheus became a partner of Thomas Appleton, but for most of his life from 1814 he worked with a succession of wealthy merchants, of whom George Mackay and John Klemm were the most prominent. Babcock’s pianos usually have a plaque in which the name of the merchant predominates. The plaque of our piano says “Made by A. Babcock for John G. Klemm.”

Babcock worked in Boston until 1829, and again from 1837 through his death, in 1842. He spent the years 1829-37 in Philadelphia, working for John Klemm. Our instrument, serial #188, was probably constructed at Babcock’s manufactory in Boston in 1825, and shipped to Philadelphia for sale through Klemm, prior to Babcock’s years in that city.

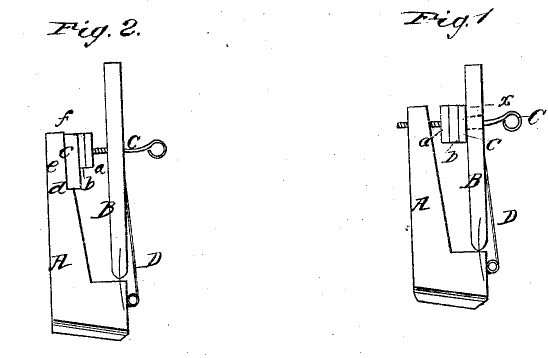

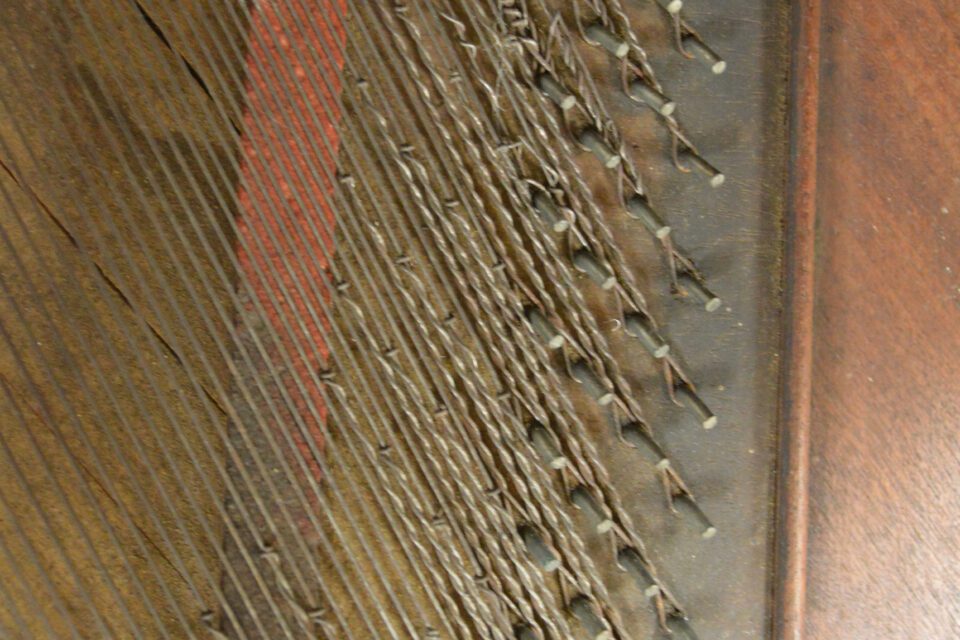

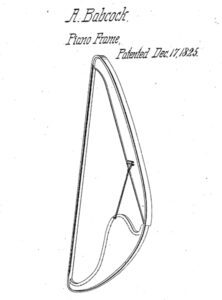

Babcock’s patent for the cast iron frame was originally filed in 1825 and re-filed in 1833, following a fire in the patent office that destroyed all records (only a drawing survives – at right). Interestingly, only three examples of Babcock’s iron frame are known to have survived, out of the total of about 100 Babcock pianos (all squares) whose whereabouts is known today. In 1830 Babcock patented the principle of “cross-stringing” (running a string from a tuning pin, around a hitch pin or fixture of some nature, and back to a second tuning pin), with a number of options aimed at shortening the the back length of the string between the bridge and the hitch fixture. See the patent text for Babcock’s own words. [In reading the patent text, note that “pin block” refers to the point where the hitch pins are attached, not the tuning pin block].

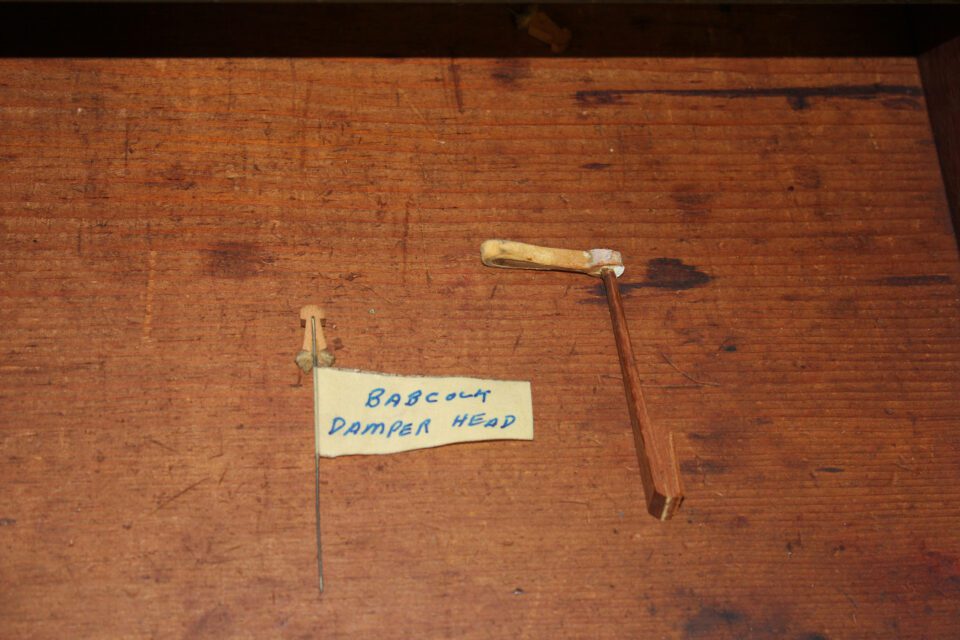

When he returned to Boston in 1837 Babcock worked for Jonas Chickering, and seems to have been responsible for Chickering’s adoption of the cast iron plate. Babcock also patented action improvements in 1839, and experimented with various ways to cover hammer heads, including the use of a piece of lead toward the tip of the hammer molding to add mass to the hammer (patented by Babcock’s partner John Mackay in 1828).